Drilling

Preparation for drilling

Process

There are 3 separate processes that have to be achieved in order to drill a ball for a bowler.

First, we need the measurements for the bowler’s hand, whether that is copying previous measurements, or taking new ones (see chapter – Fitting).

Second, we need to know where on the ball surface we are going to drill the holes (Yes, it does matter). Determining the location of the holes (see chapter – Layouts).

Third, is the process of physically drilling the holes in the ball. We will cover that step by step in this chapter, and we will assume that you already have the measurements and that it has already been determined where you want to drill the holes.

Prepare necessary equipment and tools

Milling machine / Drill press - Make sure it's clean when you start the job and that the pitches have been calibrated

Drill bits - Make sure they have been sharpened recently

Ruler - Span ruler that is accurate to at least 1/16" - Having a post to secure it can be handy

Bevel sander - We recommend putting on a new sanding disc for every ball you drill for consistancy

Grease pencils / pin point scriber - For drawing the reference lines on the ball. If you want to use a scriber, make sure it's ok with the customer

Instant cure glue - For installing finger inserts, thumb inserts, thumb slugs and interchangeable thumbs

Drilling Options

Step by step instructions on how to drill the holes in a bowling ball

Option #1 – Drilling the finger holes first

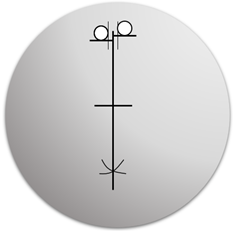

1) Draw centre line and midline of grip

2) Dividing the span of the middle finger in half, draw the span line for the middle finger and ring fingers

3) Draw bridge lines

4) Select the correct drill bit for the middle finger and set the correct pitches

5) Align the drill bit so that the cutting edges are lined up to just touch the bridge line and span line

6) Drill middle finger hole

7) Repeat steps 4 – 6 for the ring finger

8) If the specs (measurements) call for finger inserts, bevel the edges of the holes slightly and install them now

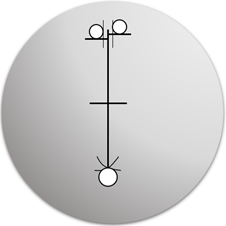

9) Using a ruler that is accurate to at least 1/16”, place it at the bottom centre of the middle finger hole

10) Refer to spec sheet for the middle finger span

11) Measure from the middle finger along the centre line and mark the exact span distance by drawing an arc

12) Repeat steps 10 & 11 for the ring finger

13) Select the correct drill bit for the thumb and set the correct pitches

14) Align the drill bit so that the centre of the drill bit is on the centre line and so the cutting edge of the bit will just touch the spot where the 2 arcs intersect

15) Drill the hole

Option #2 - Drilling the thumb hole first

1 1) Draw center line and midline of grip

2) Dividing the span of the middle finger in half, draw the span line for the thumb hole

3) Select correct drill bit for the thumb hole

4) Set the correct pitches

5) Align the drill bit so that the tip of the bit is on the centerline and the front of the bit just touches the span line

6) Drill thumb hole

7) Using a span ruler accurate to 1/16”, place the clip on the front edge of the thumb hole

8) Refer to the spec sheet for span measurements

9) If installing finger inserts, measure the thickness of the front edge of the insert and subtract that amount from the total span (Example: the total span is 4 1/2” and the insert is 3/16” then the edge to edge or cut span is 4 5/16”)

10) Measure from the front edge of the thumb hole to a point 1/2” to the left and 1/2” to the right of the centerline, and mark the span lines

11) Draw bridge lines (1/4” for fingertip w/inserts, 3/8” for conventional)

12) Select the correct drill bit and set the pitches for the middle finger

13) Align drill bit so that the edge of the drill bit is set to just touch the span line and the bridge line.

14) Drill hole for middle finger. 1 1/2” deep for fingertip w/inserts and 2 1/4” deep for conventional

15) Repeat steps 12 – 14 for the ring finger hole

16) Bevel finger holes and install the inserts if necessary

Drilling oval holes

Many thumbs are not round, and drilling an oval hole can give those customers a more comfortable and more useful fit

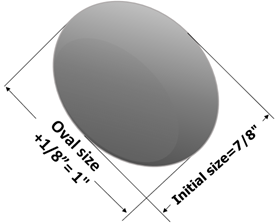

As an example, a customer’s thumb is 7/8” from front to back but is 1” from side to side

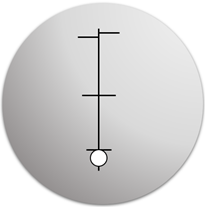

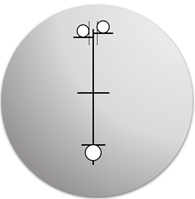

1) Set the correct pitches for the pilot hole (first cut) of the oval

2) Select the starting bit (should be the same as the front to back measurement of the thumb)

3) Drill the pilot hole

4) Move the table according to the calculations that Spectre has given you and make the next cut

5) Continue the procedure until you have made the final cut and confirm the correct side to side measurement with a calipers

6) Make sure to follow the movements calculated by Spectre to assure the smoothest oval with the least amount of finishing work

Finishing work

Beveling

Beveling is a procedure that is very important in making sure that every ball for the same bowler feels the same. Different amount of bevel can make the span feel either longer or shorter, therefore it is important to practice for consistency

It is recommended that you use a brand new sanding disk with every ball you do. This will make it easier to be more consistent

Finger Inserts

Finger inserts must be glued into the ball by rule so that they will not fall out and they are flush with the surface of the ball. Good technicians should be able to glue the grips in effectively with only 3 or 4 drops of super glue placed properly

Thumb slugs and Interchangeable thumb inserts

The majority of higher level bowlers will use either a slug or an interchangeable thumb insert to give them a more consistent feel from one ball to another. When using a slug or an interchangeable insert, double check your math to make sure that you end up with the correct span after it is installed